Auto Light Lens Manufacturer – Automotive Interior Mould – JS Mould

Short Description:

Auto Light Lens Manufacturer – Automotive Interior Mould – JS Mould Detail:

Description

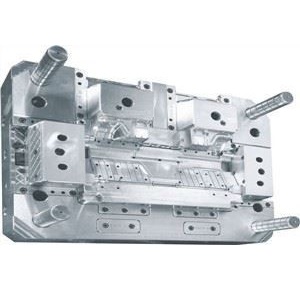

JS MOULD Mold provides automotive Interior moulds for international automotive OEM brands. We produce car Interior molding with excellent quality and short delivery.

For Interior mold tooling, high precision is very important.Such as door trims products have high requirements on the appearance. We also make dashboard mould, door inner panel mould, AB boss mould.

Usually, door trim will be requested for texture. On the product, it can not appear welding line, ejector white mark, shrinkage mark, and deformation. And we JS MOULD Mold have well experience in making these molds,we know how to make the best design for them.And below is the regular specification for automotive Interior moulds

|

Items |

Description |

|

Business type: |

Manufacturer |

|

Product Name |

Automotive Interior mould |

|

Maximum Mould Size |

1000*1000 mm |

|

Cavity |

Single/Multi |

|

Runner |

Hot/Cold Runner |

|

Specification |

Depends on customer’s requirements. |

|

Surface Treatment |

texture,Polish,painting,screen printing,turnkey project |

|

Mold hot runner |

DME, HASCO, YUDO,etc |

|

Mold cold runner |

point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

|

Surface of Mould |

EDM / High Polish&Texture |

|

Mould Life |

300,000-1,000,000 shots |

|

Mould Core |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

|

Hardness of steel |

46~56 HRC |

|

Molud Standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

|

Mould Base |

LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

|

Mold hot treatment |

quencher, nitridation, tempering,etc. |

|

Surface finish of Part |

Logo print,Texture,Polishing,Painting,Chrome Plating |

|

Plastic material |

PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,HIPS, PMMA etc. |

|

Outside package |

Standard wooden casesor as your requirement |

|

Inner package |

Stretch waterproof film & Each Mold painted ,anti-rust oil.3. Spare parts together with the mold shipment. |

|

Mold cooling system |

water cooling or Beryllium bronze cooling, etc. |

|

Trade terms |

FOB Shenzheng,EXW ,CIF |

|

Export to |

Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

Product detail pictures:

Related Product Guide:

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Auto Light Lens Manufacturer – Automotive Interior Mould – JS Mould, The product will supply to all over the world, such as: Hongkong, Lithuania, Washington, Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!