car seat Plastic mould Supplier – Auto Parts Mould – JS Mould

Short Description:

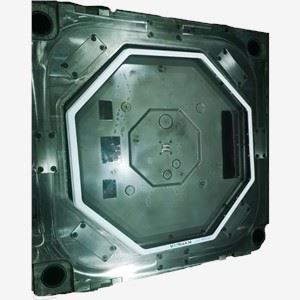

car seat Plastic mould Supplier – Auto Parts Mould – JS Mould Detail:

Description

JS MOULD Mold provides full plastic injection mold manufacturing services,utilizing an in-house tooling room with the craftsmanship and expertise to develop new mold projects and managed by JS MOULD rich experienced engineering technicians. Using our EDM technology, CNC machinery, and the good skills of our senior mould makers to meet high quality & tolerance plastic mould and specific surface finish.

Base information of aoto parts mould as below:

No of Cavities: Single or Multi cavity

Mould Standard: Customized standard

Mold base: LKM, HASCO, DME equivalent and customized.

Injection System: hot runner,cold runner,

Production Material: PMMA, PPS,PC, POM, PBT, PP, PA66, PA6, PE, HDPE, ABS, TPE, TPU, PET, SAN, etc.

Design software: UG software.

Core & Cavity Material: S136,H13, S7, NAK80, SS420, P20 and other steel according to customer mould requirement.

Type of gating: Side gate, Sub gate, Pin point gate, Edge gate etc

Surface finish: Texture,VDI EDM, SPI standard, etc

Hot runner: Incoe,Mold Masters, Yudo, Synventive, etc.

Hydraulic cylinder:STAUBU, PARKER, TAIYO, JUFAN

Treatment: Heat Treatment,Chrome Plating ,etc.

Lead time: 4~8 weeks

Shot life: 1,000,000

Hot Tags: auto parts mould, China, manufacturers, factory, made in China, Plastic mould manufacturer, mold supplier for washer, Aerospace plastic molds, auto parts injection, box injection mould, performs injection mould

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for car seat Plastic mould Supplier – Auto Parts Mould – JS Mould, The product will supply to all over the world, such as: Muscat, Panama, Libya, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!