China wholesale Medical Fitness Equipment Mould Quotes – China PP Plastic Buttons For Medical Instrument – JS Mould

Short Description:

China wholesale Medical Fitness Equipment Mould Quotes – China PP Plastic Buttons For Medical Instrument – JS Mould Detail:

Description

JS MOULD mold not only provides plastic mold,but also provide injection molding for medical Instrument.In general, plastics offer benefits over other materials and processes in the areas of design flexibility, overall cost-effectiveness and speed of production.

Consider the following materials for your project:

Silicone — For components and parts where flexibility is a key requirement, silicone is often the material of choice. It offers exceptional durability and biocompatibility and is very cost-effective at high volume production runs.

Polycarbonate — This is one of the strongest materials available, with high impact and vibration resistance. Polycarbonate is ideal for components where visibility is a benefit because it can be manufactured to be almost completely transparent. It is also highly resistant to heat and UV light.

Polyethylene — With a high molecular weight, polyethylene is ideally suited for the surfaces of prosthetics and wearable devices due to its appearance, durability and relative smoothness. It is high-strength and cost-effective but cannot be sterilized via autoclave.

Polypropylene — This material is ideal for components that must be repeatedly sterilized via autoclave, thanks to its high heat resistance. It also demonstrates exceptional radiation resistance.

With these tips in hand, you’ll be able to make an informed decision about the material and process that’s best for your medical device or component manufacturing.

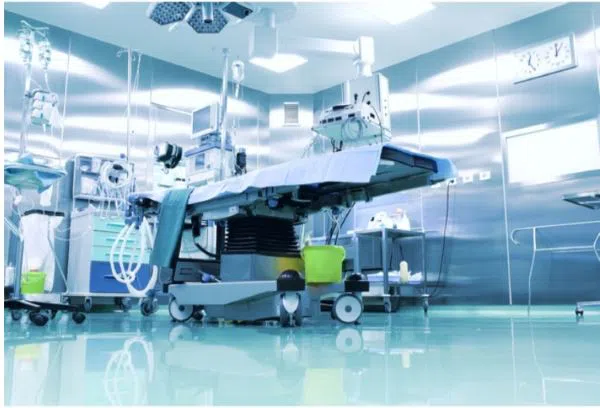

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for China wholesale Medical Fitness Equipment Mould Quotes – China PP Plastic Buttons For Medical Instrument – JS Mould, The product will supply to all over the world, such as: Macedonia, Latvia, Estonia, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.